Standaryzowane przeróbki i ponowne testowanie: Profesjonalne przeróbki wykrytych wad lutowania. Proces przeróbek musi ściśle przestrzegać specyfikacji, przy użyciu odpowiednich narzędzi i materiałów, aby uniknąć wtórnych uszkodzeń. Przerobione PCBA muszą zostać ponownie przetestowane, aby potwierdzić rozwiązanie i brak nowych problemów.

Analiza przyczyn źródłowych (RCA): Przeprowadź dogłębną analizę wad lutowania o wysokiej częstotliwości lub krytycznych, aby zidentyfikować ich prawdziwe przyczyny. Może to obejmować parametry drukowania pasty lutowniczej, dokładność maszyny pick-and-place, profile temperatury reflow, aktywność topnika, projekt padów, jakość PCB, a nawet zgodność operatora podczas produkcji PCBA.

Kontrola i optymalizacja procesu: Na podstawie ustaleń RCA dostosuj parametry produkcji PCBA, konserwuj sprzęt, udoskonalaj procesy i ulepszaj szkolenia. Na przykład zoptymalizuj profile temperatury pieca reflow, aby zmniejszyć liczbę pustych przestrzeni, ulepsz projekt szablonu do drukowania pasty lutowniczej, aby rozwiązać problem mostkowania lub niewystarczającej ilości lutu lub zaostrz kryteria kontroli AOI, aby poprawić wskaźniki wykrywania wad.

Analiza danych i pętla sprzężenia zwrotnego: Wykorzystaj zgromadzone dane testowe i inspekcyjne do analizy trendów, statystyk wydajności i analizy trybu awarii. Terminowe sprzężenie zwrotne do zespołów ds. badań i rozwoju, projektowania i inżynierii produkcji tworzy zamknięty system ciągłej poprawy, rozwiązując problemy z jakością lutowania u źródła.

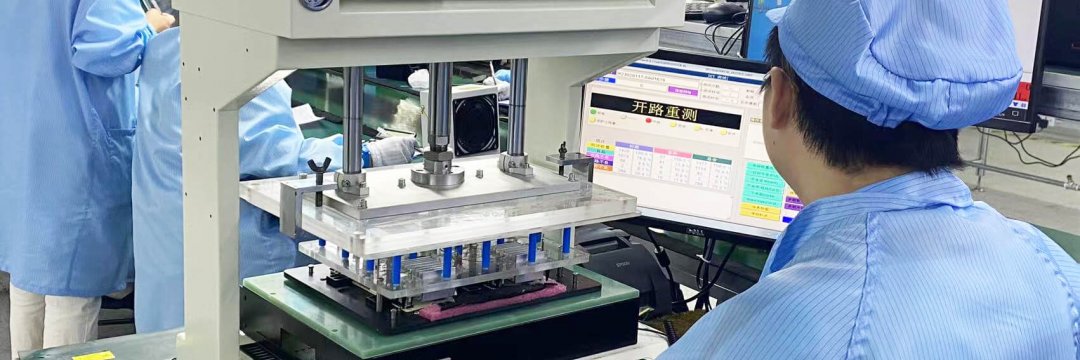

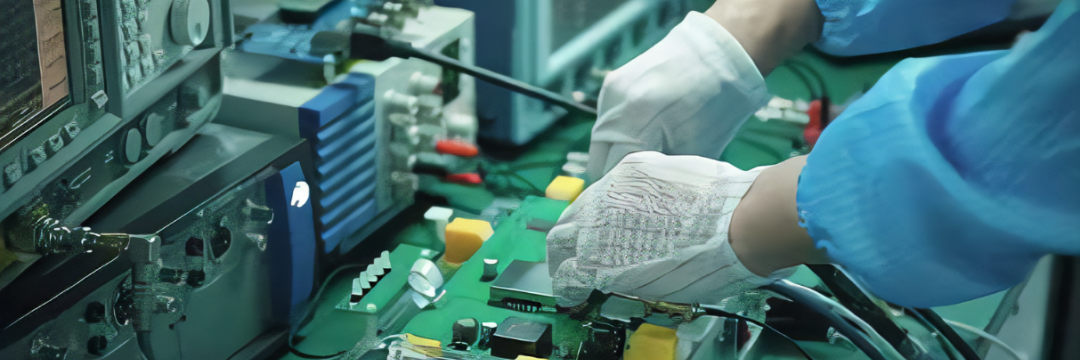

Jakość lutowania jest kołem ratunkowym niezawodności PCBA, a jej rygorystyczna kontrola i zarządzanie są kluczowe dla systemu testowania PCBA. Dzięki zastosowaniu SPI, AOI, promieni rentgenowskich i innych metod kontroli na różnych etapach produkcji PCBA, w połączeniu z ICT i FCT w celu walidacji funkcjonalności elektrycznej, wady można skutecznie wykrywać. Co ważniejsze, analiza przyczyn źródłowych zidentyfikowanych problemów i sprzężenie zwrotne danych do procesu produkcyjnego umożliwiają ciągłą poprawę. Tylko poprzez integrację zaawansowanych technologii kontroli z naukowymi metodami zarządzania można wytwarzać produkty PCBA o wysokiej wydajności i wysokiej niezawodności.

read more