Zrychlené ověřování PCBA: Jak zkrátit dobu ze 7 dnů na 3 dny?

Výroba elektroniky vzkvétá díky r

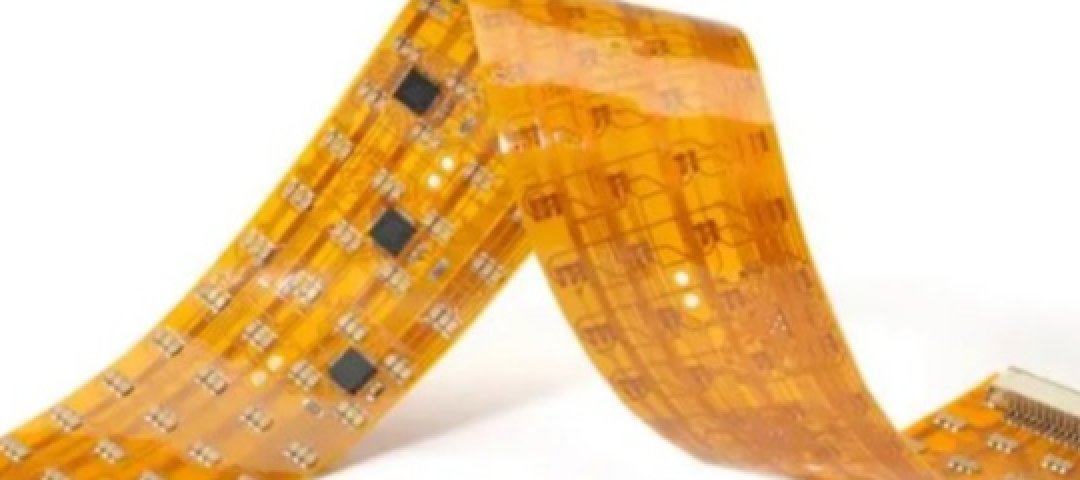

Sestava flexibilní obvodové karty je tištěný obvod navržený na tenké a pružné izolační fólii. Jeho charakteristická vlastnost je tak měkká, že se dá ohýbat a skládat pomocí pokročilé technologie, čímž se transformuje elektronický průmysl. Jaký je rozdíl mezi flexibilní sestavou tištěných spojů a pevnou deskou plošných spojů spočívá v tom, že flexibilní sestava plošných spojů může mít jakýkoli tvar, který zákazníci vyžadují, a hraje důležitou roli v aplikacích, jako jsou displeje, nositelná zařízení a lékařské vybavení.

1. Definice flexibilní montáže PCB?

Flexibilní sestava PCB je běžně vyrobena z vysoce flexibilního materiálu, jako je polyimid, a elektronické součástky jsou sestaveny do flexibilních materiálů pro výrobu PCB. Díky metodám SMT nebo THT lze desku plošných spojů ohýbáním a skládáním měnit do různých tvarů a přitom si zachovat vlastní funkčnost. Díky svým výhodám je výrobce desek plošných spojů pcba oblíbený a převládá v prostorově omezených, kompaktních nebo mobilních zařízeních

2. Výhody výroby flexibilních desek plošných spojů

(1.) Zvýšení využití prostoru: Flexibilní sestava desek s plošnými spoji maximálně využívá prostor a lze ji použít pro malá a kompaktní elektronická zařízení.

(2.) Být flexibilní: díky své pružnosti se nedá snadno rozbít. Bez ohledu na to, zda vibruje nebo se pohybuje, nebude mít žádné problémy.

(3.) Snížení hmotnosti: Nízká hmotnost je pro některá přenosná zařízení velmi důležitá a sestava flexibilních desek plošných spojů je ideální volbou pro přenosná zařízení s výhodou měkké a nízké hmotnosti.

(4.) Snižující se chybovost: Čím méně propojení a pájených spojů mají, tím menší je pravděpodobnost selhání desky plošných spojů a sestavy

(5.) Zvyšování zisků: Proces výroby flexibilních desek plošných spojů je jednoduchý a přímo vede ke snížení celkových výrobních nákladů.

3. Sestava flexibilní desky plošných spojů VS sestava pevné desky plošných spojů

Umístění komponent

Technologie povrchové montáže (SMT) je široce používána ve vzorcích flexibilních PCB sestav a hromadné objednávky jsou dokončovány pomocí automatických pick-and-place strojů. Existují však některé problémy, kterým je třeba věnovat pozornost během procesu sestavování desky plošných spojů:

(1) Deska by měla být pevně a přísně nastavena na vakuový stůl nebo specializované svorky, aby se zabránilo posunu nebo pohybu během umístění.

(2) Potřebuje co nejvíce snížit napětí na palubě, pokud jde o přetavení, a ostré ohyby jsou teoreticky zakázány.

(3)Pokud jde o větší součásti, nemůže zůstat na místě během přetavení bez pomoci mechanických nástavců, jako je pájecí pasta, lepicí tečky nebo tavné čepy.

(4) Přesné umístění je kritické, protože jakákoli nesouosost může mít za následek posunutí desky výrobce PCB během přetavení.

Přeformátovat

Jak všichni víme, pájení součástek pro povrchovou montáž se obvykle provádí pomocí přetavovacích pecí, podobných těm, které se používají pro montáž pevných desek plošných spojů. Jsou však vyžadovány specifické konfigurace a techniky:

1. Měly by být aplikovány postupné změny teploty, aby se zabránilo nadměrnému namáhání sestavy flexibilní desky s plošnými spoji během procesu zahřívání.

2. Špičkové teploty musí být pečlivě kontrolovány podle vlastností podkladového materiálu.

3.Přijměte opatření k zamezení oxidace.

4. Deska s plošnými spoji a sestava musí být perfektně na svém místě, aby se zabránilo jakémukoli pohybu během přetavení. Vakuové stoly jsou běžně vyžadovány.

5. Zajištění správného poloměru ohybu je zásadní, aby se zabránilo poškození těsnými záhyby během pájení přetavením.

Kontrola a testování

Aby se minimalizovalo riziko, je u flexibilních obvodů nezbytná důkladná kontrola a testování:

A. Automatická optická kontrola (AOI): Použijte kamery s vysokým rozlišením a software pro zpracování obrazu k automatické detekci defektů na povrchu sestavených desek plošných spojů, jako jsou špatné pájené spoje, nesouosost součástí, chybějící díly atd.

b. Funkční testování: Integrujte sestavenou desku plošných spojů do produktu a proveďte skutečné provozní testy, abyste ověřili její funkce a výkon.

C. Testování prostředí: Testujte výkon montáže desek plošných spojů za různých podmínek prostředí (jako je vysoká teplota, nízká teplota, vlhkost, vibrace atd.)

d. Vizuální kontrola: Prohlédněte povrch základní desky pouhým okem nebo pod mikroskopem, abyste hledali zjevné vady, jako jsou špatné pájené spoje, špatně zarovnané součásti, chybějící části atd.

E. Testování pájitelnosti: Testujte pájecí výkon pájených spojů a otvorů, abyste zajistili hladký proces pájení

4, Aplikace flexibilní montáže PCB

(1) Spotřební elektronika: Flexibilní sestava desek plošných spojů je nezbytná pro kompaktní a adaptabilní návrhy v zařízeních, jako jsou flexibilní displeje, nositelné technologie, chytré telefony, tablety a herní konzole.

(2) Automobilový průmysl: Sestava flexibilních desek plošných spojů se běžně používá v automobilových systémech, včetně sdružených přístrojů, informačních a zábavních systémů a pokročilých asistenčních systémů pro řidiče (ADAS).

(3) Letecký a kosmický průmysl a obrana: Lehká a odolná povaha flexibilních desek plošných spojů je předurčuje pro letecké a obranné aplikace, jako jsou satelity, letecká elektronika a vojenské vybavení.

(4) Lékařská zařízení: Flexibilní design desek plošných spojů hraje zásadní roli u lékařských zařízení, včetně kardiostimulátorů, naslouchátek a lékařských zobrazovacích zařízení, které jsou ceněny pro svou flexibilitu, biokompatibilitu a kompaktní design.

Průmyslová automatizace: Díky své vysoké přesnosti a spolehlivosti se flexibilní deska plošných spojů často používá v průmyslových řídicích systémech, robotice, senzorech a komunikačních modulech.

Závěr

Flexibilní deska s plošnými spoji přináší špičková řešení pro kompaktní, lehká a flexibilní zařízení, která přináší revoluci v elektronickém průmyslu. Jeho výhody v oblasti vesmírné efektivity, odolnosti a spolehlivosti z něj udělaly nejlepší volbu v odvětvích, jako je spotřební elektronika, automobilový průmysl, letecký průmysl, lékařská zařízení a průmyslová automatizace.

V případě jakýchkoli dotazů nebo požadavků na výrobu flexibilních desek plošných spojů nás prosím neváhejte kontaktovat pro více informací. Jako spolehlivý výrobce PCBA, jednatel XW S více než desetiletými zkušenostmi v odvětví flexibilních montáží desek plošných spojů vám můžeme přizpůsobit nejvhodnější, pokročilou službu PCB a PCBA, reagovat do 2 hodin a nabídnout vám nejefektivnější řešení návrhu a montáže desek plošných spojů.