The Hidden Lifespan Killer: How Solder Temperature Dictates Your PCBA's Fate

Ever wonder why some electronics seem to chug a

12+ years experience and 300+ engineers working with overseas projects

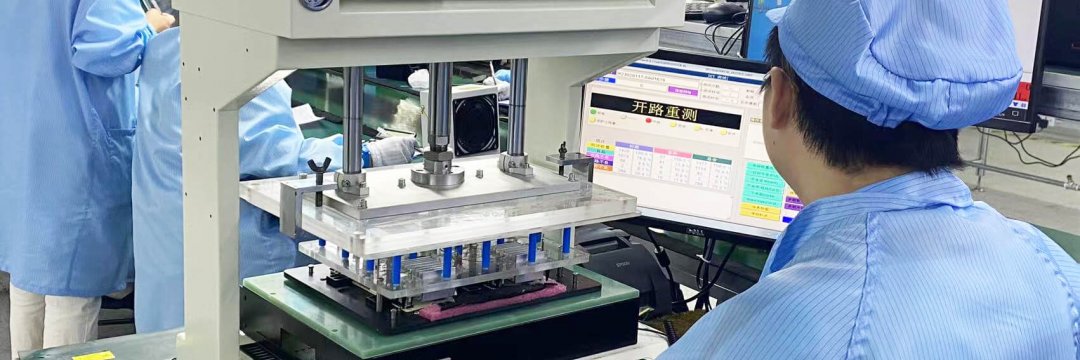

ISO9001:2015, ISO14001, ISO13485, ROHS, and UL

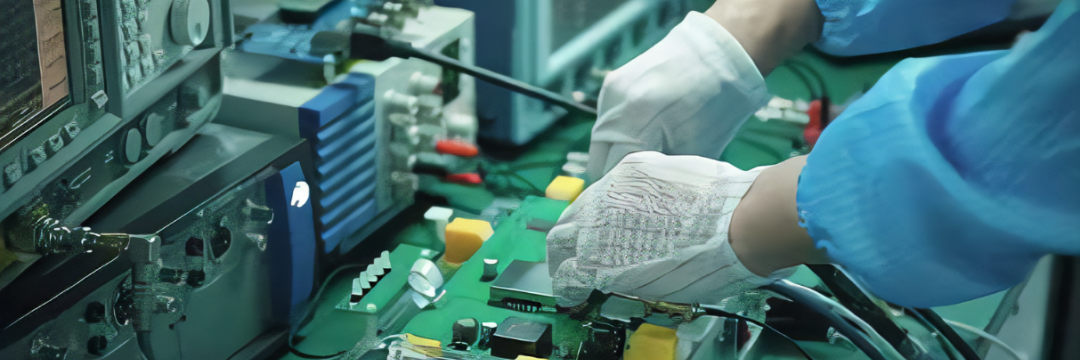

designing, engineering, prototyping, and production and after-sales services

Coverage of over 150 countries and over 3,600 customers

Respond to your request within one hour, we provide 7/24 hours support for customers in different time zones

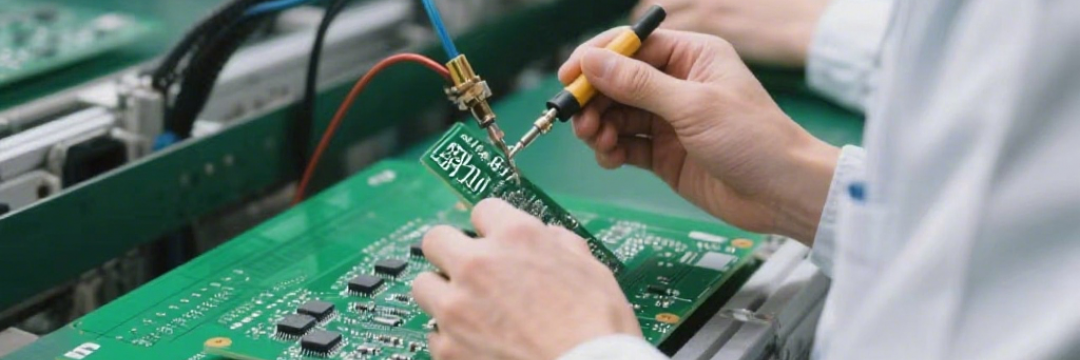

SMT lines + Automatic plug-in production line + Wave soldering lines + Assembly lines