The Hidden Lifespan Killer: How Solder Temperature Dictates Your PCBA's Fate

Ever wonder why some electronics seem to chug a

In the competitive world of electronics manufacturing, reducing costs without compromising quality is a challenge for every company. Printed circuit board assemblies (PCBAs) represent a significant portion of the cost structure of many electronic products. Here are some strategies for optimizing design, supply chain management, and production processes to reduce costs while maintaining high quality standards.

Design Optimization

1. Standardization: Use standardized components and modules whenever possible. This reduces the need for custom parts, which can be more expensive and time-consuming to produce.

2. Design for Manufacturability (DFM): Simplify the design for easier and more cost-effective manufacturing. This includes reducing the number of components, using surface-mount technology (SMT) for smaller components, and designing for automated assembly.

3. Component Sourcing: Favor readily available components from multiple sources. This can help you negotiate better prices and avoid shortages.

Supply Chain Management

1. Supplier Relationships: Build strong relationships with suppliers to negotiate better prices and terms. Long-term partnerships can earn you discounts and priority service.

2. Inventory Management: Implement just-in-time (JIT) inventory management practices to reduce carrying costs and minimize the risk of obsolescence. Accurate demand forecasting is essential to this success.

3. Global Sourcing: Consider sourcing components from regions with lower labor costs, but be sure to factor in shipping costs, customs duties, and potential quality risks.

Production Process Optimization

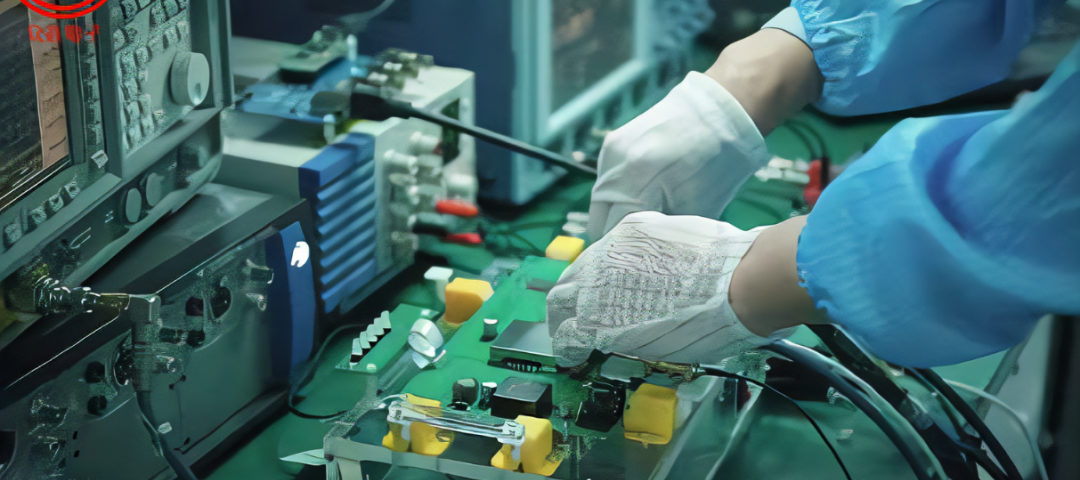

1. Automated Assembly: Invest in automated assembly lines to increase efficiency and reduce labor costs. Automation can also improve consistency and quality. 2. Process Improvement: Continuously review and improve your production processes by applying lean manufacturing principles. This may involve reducing waste, streamlining workflows, and improving employee training.

3. Quality Control: Implement rigorous quality control measures to minimize defects and rework. This not only reduces costs but also preserves product integrity.

Maintaining Quality Standards

While reducing costs, it is essential to maintain high quality standards. Here's how:

1. Certified Manufacturers: Partner with ISO-certified PCB manufacturers and ensure they have the necessary quality management systems in place.

2. Testing and Validation: Integrate rigorous testing and validation procedures into every stage of production to detect defects as early as possible.

3. Quality Feedback Loop: Establish a feedback loop between the field and the production team. Use customer feedback and field reports to continuously improve designs and processes.

In conclusion, reducing PCB costs without compromising quality is a multifaceted approach that involves rigorous planning and execution throughout design, the supply chain, and production. By leveraging standardization, building strong supplier relationships, optimizing production processes, and maintaining a commitment to quality, companies can achieve savings without compromising the integrity of their products. Remember, the goal isn't just to reduce costs, but to do so in a way that increases your product's overall market value.