Zrychlené ověřování PCBA: Jak zkrátit dobu ze 7 dnů na 3 dny?

Výroba elektroniky vzkvétá díky r

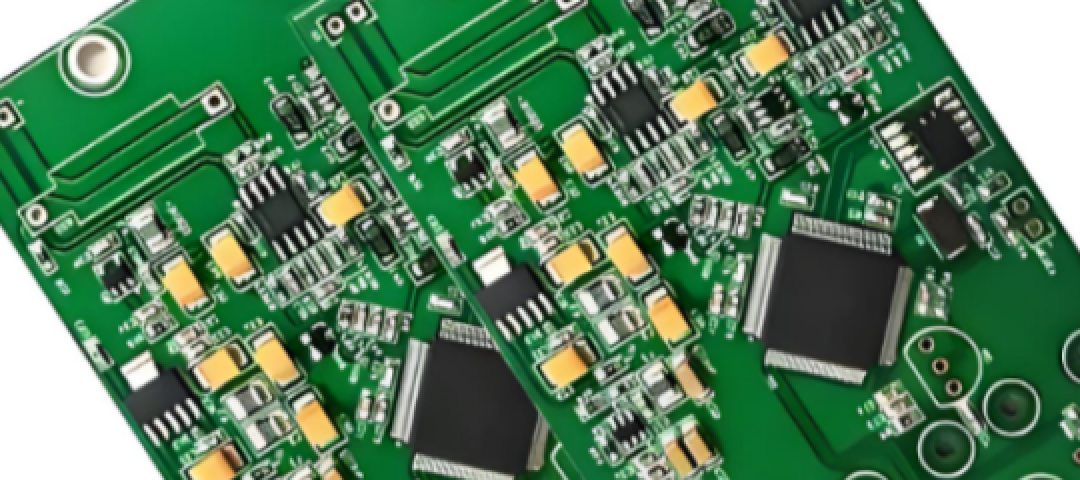

Moderní elektronika, jako jsou mobilní telefony, IPAD, mobilní hodinky, obohacují naše životy a PCB, deska s plošnými spoji je jádrem elektroniky a poté montáže PCB (PCBA), aby elektronika fungovala normálně. Desky plošných spojů mohou být vyrobeny až ze 40 vrstev a běžným materiálem je Fr4 a široce se používají téměř ve všech průmyslových odvětvích.

1. Význam vrstev DPS

Elektrická konektivita: Struktura vrstvy hraje zásadní roli v elektrickém výkonu a funkci desky plošných spojů, takže distribucí vodivých vodičů přes více vrstev lze účinně zaručit tok signálu a výrazně snížit rušení, takže deska plošných spojů je vhodná pro stále složitější situace.

Minimalizace prostoru: Vertikální skládání vrstev pomáhá zmenšit celou velikost PCB a maximalizovat využití prostoru, díky čemuž PCB hraje větší roli v omezeném prostoru miniaturizovaných elektronických zařízení, včetně nositelných zařízení, chytrých telefonů a zařízení internetu věcí.

2. Různé typy vrstev PCB

(1.)Signálové vrstvy: Hlavní vodivá vrstva, která je zodpovědná za přenos elektrických signálů mezi komponenty, je signálová vrstva. Skládající se z měděných vodičů spojujících různé komponenty, signálová vrstva zajišťující přesnost a stabilní přenos a směrování signálu a složitost obvodu a potřeby návrhu nakonec určují počet signálových vrstev.

(2.)Uzemňovací rovina: Součást poskytuje stabilní energii v PCB je napájecí zdroj a vrstva vyhrazená pro referenci zpětné cesty signálu je zemní plocha. Tyto dva spolupracují, aby zajistily konzistentní distribuci energie napříč PCB a snížily hluk a pokles napětí. Jako nízkoimpedanční cesta vyhrazená pro zpětný proud pomáhá zemnící plocha zvýšit přesnost signálu a snižuje elektromagnetické rušení (EMI) během provozu PCB.

(3.)Interní vrstvy: Vnitřní vrstva je obvykle umístěna mezi vnějšími signálovými vrstvami vícevrstvé desky plošných spojů. Vnitřní vrstva umožňuje, aby byl návrh desky plošných spojů flexibilnější a komplexnější, protože hraje mnoho důležitých rolí v celé desce plošných spojů, včetně distribuce napájení, vedení řídicí impedance, stínění šumu od citlivých signálů a poskytování většího prostoru pro směrování.

3. Faktory, kterým je třeba věnovat pozornost v procesu návrhu vrstvy PCB

(1.)Kvalita signálu: Klíčem k udržení integrity signálu je správné směrování trasování a vrstvení vrstev, takže musíme pečlivě zvážit uspořádání mezi vrstvami, abychom zajistili kvalitu signálu během provozu PCB. Zároveň musíme poznamenat, že řízení impedančního směrování na konkrétní vrstvě je nezbytné pro vysokorychlostní signály, zatímco citlivé signály lze chránit před rušením šumem pomocí přidaných stínících vrstev.

(2.)Rozdělení energie: Jedním z nejdůležitějších faktorů při zajišťování provozní stability elektronických obvodů je správná distribuce energie. Vhodná konstrukce napájecího zdroje a zemní plochy může účinně snížit pokles napětí a šum a stabilní napájení desky plošných spojů, což ukazuje, že rovnováha polohy napájecího zdroje a zemní plochy hraje velkou roli při zamezení vazebných efektů a zlepšení kvality signálu.

(3.)Thermal Management: Efektivní tepelné řízení je také zásadní pro PCBS. Kombinací horkého průchozího otvoru a měděné roviny lze výrazně zvýšit rychlost odvodu tepla ze součásti, čímž se zabrání provozu nebo jiným problémům s kvalitou způsobenými přehřátím produktu, zajistí se stabilita desky plošných spojů a přinese uživateli dobrý zážitek z produktu.

(4.)Výrobce: Náklady a složitost výroby DPS bude značně ovlivněna počtem vrstev a uspořádáním, takže schopnost výrobce DPS zvládnout stohování DPS a celkovou kontrolu návrhu je obzvláště důležitá, protože to bude mít významný dopad na efektivitu celého procesu výroby DPS. Současně by se měla vzít v úvahu také proveditelnost, aby bylo zajištěno efektivní dokončení výroby bez snížení účinnosti

Závěr

Vrstva DPS poskytuje základ pro propojení a funkci elektronických součástek. Díky dobře navržené kaskádové struktuře lze maximalizovat prostor, elektrická připojení mohou být stabilnější a celkový výkon elektronických zařízení lze výrazně zlepšit.

V případě jakýchkoli dotazů nebo požadavků na montáž, výrobu karty plošných spojů nás prosím neváhejte kontaktovat pro více informací. Jako spolehlivý výrobce desek plošných spojů a desek plošných spojů má Shanghai XW bohaté zkušenosti v oboru montáže tištěných obvodů, přizpůsobíme vám nejvhodnější, pokročilou službu PCB a PCBA.