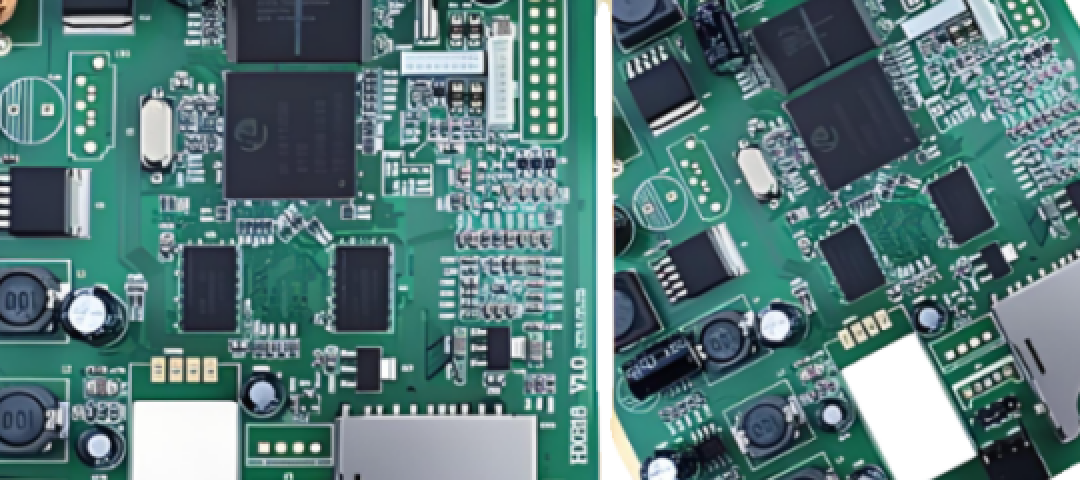

Application of MES Systems in PCBA Factories

With the advancement of Industry 4.0 and the rapid development of intelligent

It is usually complicated for PCBs manufacturing and PCB assembly. Nitrogen plays a key role during the production of PCBs to guarantee high-quality pcb prototype and bulk PCBs. What makes nitrogen essential, and what the exactly role does it play in the pcb maker process? Let’s dive into these questions in this article.

The reason why nitrogen is used?

Incorporating nitrogen into pcb printing manufacturing provides multiple benefits, such as safeguarding metal surfaces, preventing contamination, regulating moisture, and ensuring a more controlled temperature environment.

Connection betwwen nitrogen and high quality PCB production

In custom printed circuit board manufacturing, oxygen generated during the process can cause copper to oxidize, which weakens plating adhesion and conductivity, ultimately shortening the product's lifespan.

By introducing nitrogen to replace oxygen and create an inert atmosphere, copper surfaces are significantly safeguarded during key stages like etching, plating, soldering, and curing. This enhances printed circuit board maker quality and increases the product's durability.

Advantages of using nitrogen during the pcb making process

(1.)Oxidation prevention: Nitrogen plays a crucial role in print pcb board manufacturing by preventing oxidation during soldering and assembly processes. By using nitrogen, the contact between the sensitive parts and oxygen is minimized, while effectively preventing oxide layer formation on metal surfaces and ensuring clean, reliable solder joints. Without nitrogen, oxidation would be a common issue, and industry standards mandate oxygen levels below 500ppm, driving up nitrogen usage. Additionally, nitrogen improves the performance of plating tanks by maintaining temperature stability and reducing bubble formation.

(2.)Miniaturization: As technology evolves, to accommodate features like micropores and high-density interconnections, nitrogen is introduced to eliminate gas voids during the electroplating process. By flowing into the boreholes and confined spaces, nitrogen helps maintain the integrity of copper and solder coatings in small through-holes. However, for structures with blind and and buried through-holes, it is necessary to precisely calibrate the nitrogen pressure and flow rate. Without proper control, incomplete plating may result, which can compromise electrical performance or lead to delamination issues.

(3.)Automated assembly: The heat transfer characteristics of pure nitrogen can ensure that reflow welding will not cause heat damage at high temperature, and improve the quality of welding. At the same time, it also protects the sensitive element and solder paste from oxygen exposure during circuit card assembly. Inert nitrogen is often used to quickly transport printed circuit assembly through heating zones, and without nitrogen as a carrier gas, moving to a fully automated process may present more difficult. However, enhanced process control can lead to better yields and more uniform joint quality.

(4.)Maximizing reliability:Over time, oxidation may weaken the integrity of the joint or lead to part degradation. By using nitrogen, oxidation issues throughout the manufacturing and assembly process can be eliminated to reduce pcb risk and enhance product reliability.

Conclusion

The introduction of nitrogen into the PCB manufacturing process significantly improves the soldering quality, minimizes defects, prevents oxidation and contamination, and ensures long-term stability of the pcb manufacturing and pcb assembly.

16+ years experience and 300+ engineers working with overseas projects

ISO9001:2015, ISO14001, ISO13485, ROHS, and UL

designing, engineering, prototyping, and production and after-sales services

Covered 150+ countries and 3600+ customers

Reply to your inquiry within 1 hours, we provide 7/24 hours support for customers in different time zones

SMT lines+Automatic plug-in production line+Wave Soldingave Lines+Assembly lines