The Hidden Lifespan Killer: How Solder Temperature Dictates Your PCBA's Fate

Ever wonder why some electronics seem to chug a

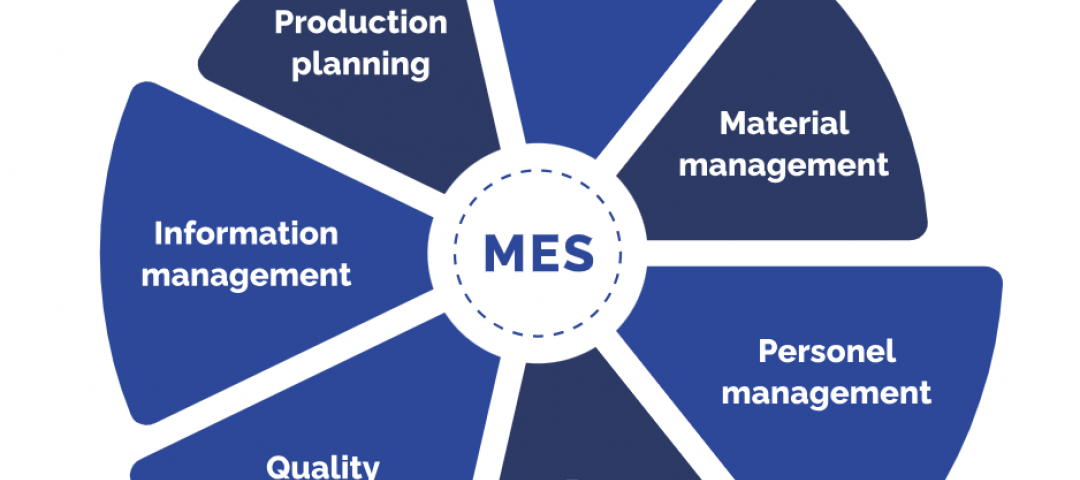

With the advancement of Industry 4.0 and the rapid development of intelligent manufacturing, Manufacturing Execution Systems (MES) are playing an increasingly important role in PCBA (Printed Circuit Board Assembly) factories as a bridge connecting enterprise management and workshop control layers. By collecting, monitoring, and analyzing production data in real-time, MES systems help enterprises achieve transparency, controllability, and intelligence in production processes, thereby enhancing production efficiency, product quality, and corporate competitiveness.

I. Challenges Faced by PCBA Factories

PCBA production processes are complex, involving a wide variety of materials, intricate procedures, and strict quality control. Traditional management models face numerous challenges:

Lack of Production Transparency: Difficulty in real-time monitoring of production progress, equipment status, and material consumption, leading to ineffective execution of production plans and extended delivery cycles.

Difficulty in Quality Control: Reliance on manual recording and tracing of production data, which is prone to errors and omissions, making it difficult to achieve full traceability and analysis of product quality.

Low Production Efficiency: Significant waste in production processes, such as waiting, handling, and rework, resulting in low production efficiency and high costs.

Severe Information Silos: Poor information flow between departments, hindering data sharing and collaborative work, and affecting overall operational efficiency.

II. The Value of MES Systems in PCBA Factories

MES systems can effectively address the aforementioned challenges faced by PCBA factories, providing the following benefits:

Achieving Production Transparency: Real-time monitoring of production progress, equipment status, and material consumption, presented visually to help managers make informed decisions.

Enhancing Product Quality: Full traceability of production processes, recording production data, process parameters, and quality inspection results for each product, facilitating quality analysis and issue tracing.

Improving Production Efficiency: Optimizing production processes, reducing waste, increasing equipment utilization and production efficiency, shortening production cycles, and lowering costs.

Breaking Information Silos: Enabling information sharing and collaborative work across departments, improving overall operational efficiency.

III. Specific Application Scenarios of MES Systems in PCBA Factories

MES systems are applied throughout the entire production process in PCBA factories, including the following scenarios:

Production Planning Management: Developing detailed production plans based on order requirements and production resources, and distributing them to workshops for execution.

Material Management: Precise management and traceability of materials, including material storage, issuance, inventory management, and material tracing.

Production Execution Management: Real-time monitoring of production progress, equipment status, and process parameters, with alerts and handling of anomalies during production.

Quality Management: Full traceability and control of product quality, including quality inspection, defective product handling, and quality analysis.

Equipment Management: Networked monitoring, fault alerts, and maintenance of equipment to improve utilization and reliability.

Data Analysis and Reporting: Analyzing and mining production data to generate various reports, providing decision-making support for managers.

IV. Key Factors for Successful MES System Implementation

To ensure the successful implementation of MES systems in PCBA factories, the following factors should be emphasized:

Clear Requirements and Rational Implementation Plans: Develop rational implementation plans based on the company's specific characteristics and actual needs, avoiding blind follow-up.

Experienced Implementation Team: Select an implementation team with rich industry experience and successful case studies to ensure project quality.

Enhanced Data Collection and System Integration: Ensure effective integration of MES systems with ERP, PLM, SCADA, and other systems to achieve data sharing and business collaboration.

Focus on Staff Training and System Maintenance: Strengthen employee training to improve operational skills and system application levels, and establish robust