Application of MES Systems in PCBA Factories

With the advancement of Industry 4.0 and the rapid development of intelligent

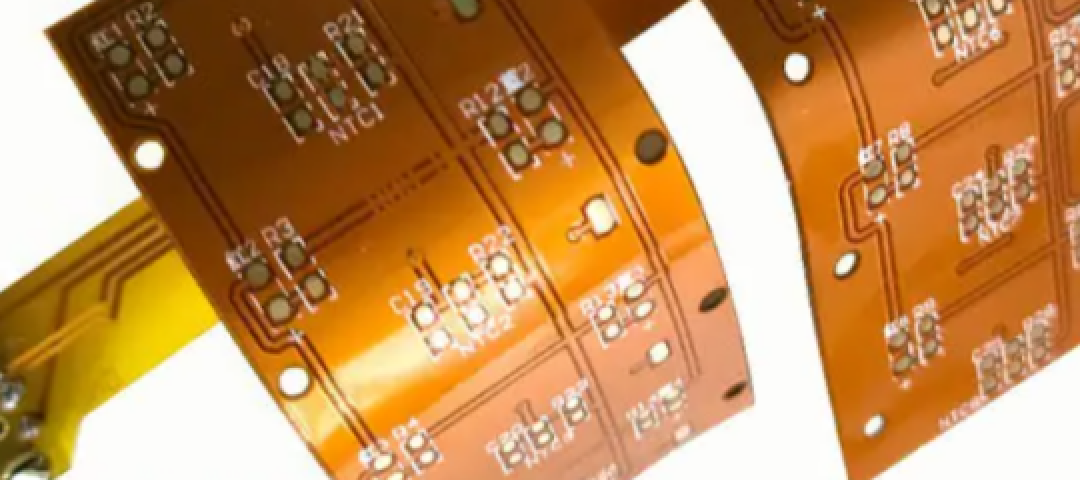

Flexible PCBA is a very important kind of PCB, because of its soft characteristics, assembled circuit board’s usage is very extensive, and the scope of application is also very wide. With the wide application of flexible PCB in production, people are more and more concerned about the production cost of flexible pcba circuit board compared to rigid printed circuit board assy?

1.Expensive Cost of Raw material

Flexible PCBs raw materials are usually made of polyimide or polyester, both of which are more expensive to produce, especially compared to the FR-4 PCB material used in rigid pcb fabrication manufacturer. The source of this high cost is due to more complex process. The production cost of polyimide the raw material used in flexible printed circuit board and assembly, is about 50 times that of FR-4. Therefore, in order to better protect the characteristics of flexible assemble pcbs, the cost of flexible PCB is much higher than that of rigid assembly of printed circuit boards in terms of raw materials.

2. Complex Manufacturing Process

Compared with rigid PCB, the production process of flexible PCB is also more complex, and the precision control of details is higher, so flexible assy pcb’s production process is longer. At the same time, due to the high requirements of flexible pcb circuit board assembly production, in the production line of flexible PCB, the current level of automation can not replace labor, and labor costs will also increase. The labor cost required to produce flexible pcb printed circuit board assembly is usually 1.2 times that of rigid PCB

3. High scrap rate

Due to the complex structure and process, the unqualified rate of flexible printed circuit board pcba sampling is often higher than that of rigid PCB, about 5-10% higher, which also leads to the rise of production costs

4.High quality requirements

Due to the complexity of the flexible PCB process and the high quality requirements of XW, we will pay more attention to the detection and control of quality in the production process, which will indirectly enhance the production cost of products

Conclusion

In summary, the production cost of flexible pcb design is much higher than that of rigid pcb board, and the main factors include: the complexity of the process, the expensive cost of raw materials and the high production scrap rate. But even if the production cost is high, due to the irreplaceable characteristics of flexible PCB, it is still an indispensable part of the PCB type

For any inquiries or requirements of the flexible PCB assembly, manufacturing, please don’t hesitate to contact us for more information. As a reliable PCB board manufacturer, XW With more than decade experience in the printed circuit assembly industry, we will customize the most suitable, advanced PCB and PCBA service for you.