The Hidden Lifespan Killer: How Solder Temperature Dictates Your PCBA's Fate

Ever wonder why some electronics seem to chug a

(1) 1-40 layers PCB manufacturing

(2) Design for manufacturing checking

(1) SMT & THT PCBA

(2) 100% buy the PCB assembly components

(3) 3D SPI, AOI, FAI, X-ray, etc equipment inspect the quality

(4) ISO 9001, ISO 14001,ISO13485, ROHS, and UL

Insert molding is one of the most efficient molding techniques, capable of firmly and perfectly combining metal and plastic to form molded parts.

Offers top-tier electronic assembly services, manufacturing complex circuit boards and electronic devices to the highest quality standards.

PCB design and layout is the process of creating the physical layout of a printed circuit board to connect electronic components in a circuit.

SCM is making resource integration of an enterprise by optimizing each link of the supply chain...

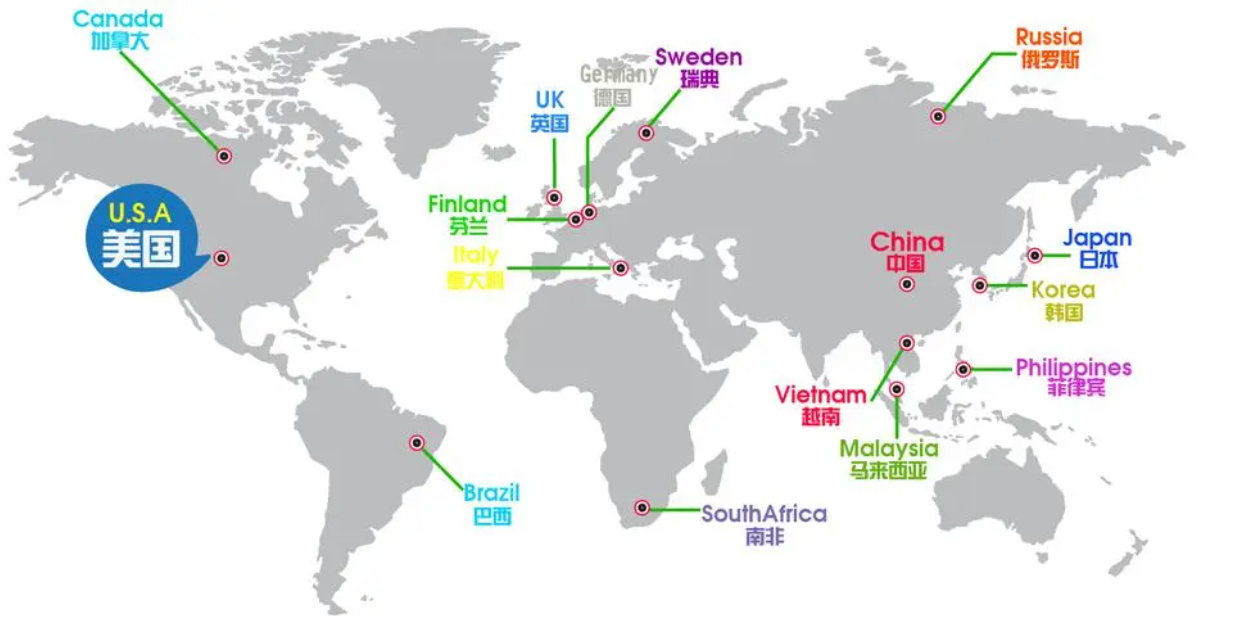

Shanghai XiangWang(XW) Electronics Equipment Co., Ltd was established in the year of 2013 in Shanghai. After 12+ years development, Shanghai XW is the forefront of high-quality and cost-effective electronic manufacturing services, ranging from PCB manufacturing and PCB assembly, and our markets are across the world, especially the North-America, Europe, Asia in different industries, including healthcare, telecommunications, electronics, automotive, industrial, renewable energy, Led and household appliances. Shanghai XW is dedicated to working with you firmly from the beginning design to perfect manufacturing and considerate after-sales service.

Shanghai XW adheres to strict quality control standards throughout the manufacturing process: IQC,IPQC,OQC, ensuring that every PCB produced meets industry standards and customer specifications.

Through economies of scale and efficient production processes, Shanghai XW can often offer competitive pricing while maintaining high quality, which makes them attractive for both large-scale production runs and smaller custom orders.

Shanghai XW can accommodate various design specifications and customization requirements from clients. We offer flexibility in terms of materials, dimensions, and manufacturing techniques to meet diverse needs.

Shanghai XW has the state-of-the-art machinery and technology, which allows for precise manufacturing processes and high-quality PCB/PCBA production.

Shanghai XW provides excellent customer support, assisting clients from initial design stages through to delivery and after-sales service, enhancing the overall client experience and ensures satisfaction.

Shanghai XW is Established in 2000, and have 300+ experienced engineers and technicians who understand the complexities of PCB, fabrication, and assembly. Their expertise ensures efficient production and reliable performance of PCBs.

12+ years experience and 300+ engineers working with overseas projects

ISO9001:2015, ISO14001, ISO13485, ROHS, and UL

designing, engineering, prototyping, and production and after-sales services

Coverage of over 150 countries and over 3,600 customers

Respond to your request within one hour, we provide 7/24 hours support for customers in different time zones

SMT lines + Automatic plug-in production line + Wave soldering lines + Assembly lines