The Hidden Lifespan Killer: How Solder Temperature Dictates Your PCBA's Fate

Ever wonder why some electronics seem to chug a

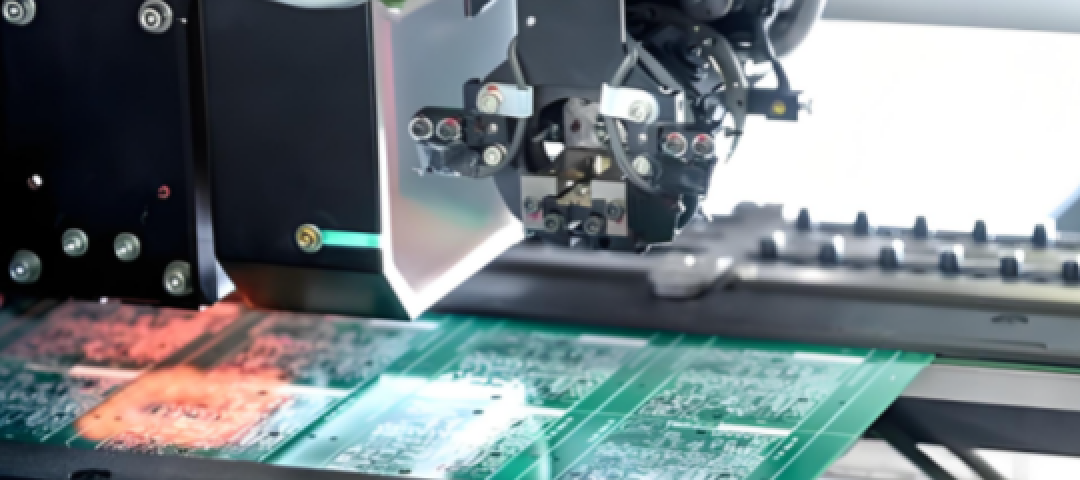

In modern PCBA (Printed Circuit Board Assembly) manufacturing, SMT (Surface Mount Technology) and BGA (Ball Grid Array) are two critical technologies. These techniques not only enhance the functional density and reliability of circuit card assembly but are also widely applied in various types of electronic products. This article explores the applications of SMT and BGA technologies in printed circuit assembly manufacturing, highlighting their advantages and selection criteria.

1.Overview of SMT (Surface Mount Technology)

SMT is a technique that directly mounts electronic components onto the surface of a circuit board. Compared to traditional Through-Hole Technology, SMT offers several advantages:

(1)Increased Component Density:

SMT enables the installation of smaller components on the PCB, enhancing the component density. This is especially crucial for modern electronic devices like smartphones, tablets, and other portable devices.

(2)Improved Electrical Performance:

The shorter leads of SMT components result in shorter electrical paths, which help improve signal transmission speed and stability.

(3)Reduced Production Costs:

SMT processes often require less manual intervention and can utilize automated assembly equipment, reducing manufacturing costs.

(4)Enhanced Reliability:

SMT components offer better resistance to vibrations and shocks, improving the overall reliability and durability of products.

In PCB assembly manufacturing, SMT technology is widely used in the production of various electronic products, including consumer electronics, communication devices, and automotive electronics.

2.Overview of BGA (Ball Grid Array)

BGA is a packaging technology where IC (Integrated Circuit) chips are connected to the circuit board via solder balls on the bottom of the package. This technology has the following features:

A.Improved Electrical Performance:

BGA packaging provides better electrical performance than traditional packaging, particularly in high-frequency applications. The solder ball layout allows for shorter electrical paths, ensuring more stable signal transmission.

B.Optimized Thermal Management:

BGA packaging is designed to effectively dissipate heat generated by IC chips, enhancing thermal management performance. This is especially important for high-power applications and high-performance processors.

C.Increased Assembly Density:

The solder ball arrangement in BGA packaging enables higher pin density, making it suitable for applications requiring high integration. This allows for efficient use of PCB manufacturing space, enhancing board-level density and overall performance.

D.Enhanced Soldering Reliability:

The evenly distributed solder joints in BGA reduce the risk of soldering defects, such as cold solder joints and short circuits, thereby improving product reliability.

In PCB board manufacturer manufacturing, BGA technology is widely used for processors, memory chips, and other highly integrated components, especially in electronic devices that require high performance and density.

3.Selection Criteria for SMT and BGA Technologies

When choosing between SMT and BGA processes, the following criteria can help ensure optimal manufacturing outcomes:

a.Design Requirements:

Select the appropriate technology based on the product's functional requirements and design. For high-integration and high-performance applications, BGA may be more suitable, while SMT is ideal for applications requiring high component density.

b.Production Costs:

SMT processes typically have lower production costs, while BGA packaging may involve higher manufacturing and testing costs. Budget considerations should be weighed accordingly.

c.Product Reliability:

Consider the product's operating environment and reliability requirements. If the product needs to withstand significant mechanical stress or harsh environments, BGA may offer better performance.

d.Technical Capabilities:

Ensure the chosen circuit board manufacturing possesses the necessary technical expertise and equipment to effectively implement SMT and BGA processes. This includes automated placement machines, soldering equipment, and testing facilities.

4. Application Examples

(1) Smartphones:

In smartphones, SMT technology is used to mount various small components, such as resistors, capacitors, and integrated circuits, while BGA technology is used for processor and memory packaging, enhancing the device's performance and reliability.

(2)Computer Motherboards:

In computer motherboards, SMT technology is used for assembling various peripheral components, while BGA technology is employed for processor and chipset packaging, ensuring the performance needs of high-performance computing.

(3)Automotive Electronics:

In automotive electronic systems, the combination of SMT and BGA technologies meets the requirements for high density and reliability, ensuring stable operation under various working conditions.

Conclusion

In printed circuit board assembly manufacturing, SMT and BGA technologies play crucial roles in increasing component density, improving electrical performance, optimizing thermal management, and enhancing reliability. Choosing the appropriate process is essential for ensuring the performance and quality of electronic products. Understanding the advantages and application areas of these technologies can help make informed decisions during PCB board assembly design and manufacturing, improving production efficiency and product quality.